Categories

Contact Us

E-mail :

rexlee@lifeipackagingmachinery.com

Hotline:

0086-0317-7751098

Mobile phone:

0086-15632306110

0086-13903277257

Address:

No. 1, Chuangxin Avenue, zone a, packaging and mechanical equipment manufacturing park, Dongguang County.

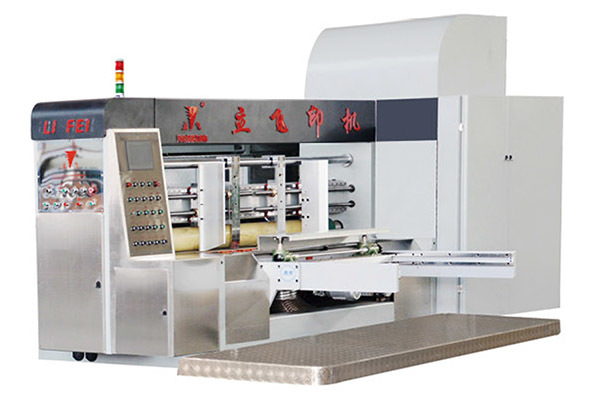

LGF-SHW Series Fixed The Whole Servo Adsorption Glazing Dry Die Cutting Machine

- Commodity name: LGF-SHW Series Fixed The Whole Servo Adsorption Glazing Dry Die Cutting Machine

- Product Details

-

★ Function and Characteristics:

● The whole line is designed and made for high qualty, high speed, high efficiency, high stability and high satety, convenient tor quick order update and operation.

● Servo control for the whole machine to reduce transmissioerror and ensure high quality printing.

● Made with high quality materials and parts.

● Vacuum transfer system for all printers.

● AlI electric, electronic and pneumatic components are of European standard.

● The whole line is of computer-centralized control.

● Equipped with I.R curing system to dry the printing ink.

● Simple transmission structure for the whole machine.

● Optional equipment-U.V. Varmishing system.

● Able to reach high Lpl precise printing reault.

● Short-time order update to improve production efficiency.

● Fixed structure for convenient change of the production orders without the need to stop the whole line.

● All units are fixed together, adopts vacuum transtering bevice printing register is serro controlled to achieve high resolution precise printing.★ Speifications:

Data / Model 900 × 2200 900 × 2600 1200 × 2200 1200 × 2600 Max. mechanic speed (pcs/min) 250 250 220 220 Max. feeding size (mm) 880 × 2000 880 × 2400 1180 × 2000 1180 × 2400 Min. feeding size (mm) 320 × 650 320 × 650 420 × 650 420 × 650 Skip feeding (mm) 1100 × 2000 1100 × 2400 1500 × 2400 1500 × 2400 Max. printing area (mm) 800 × 1800 800 × 2200 1150 × 1800 1150 × 2200 Max.thickness of board (mm) 7.2 7.2 7.2 7.2 Min. slotting size

Slotting type L.(mm)240 × 80 × 240 × 80 240x × 80 × 240 × 80 240 × 90 × 240 × 90 240 × 90 × 240 × 90 Max. slot depth (mm) 230 230 320 320 Max. thickness of boar (mm) 12 12 12 12

● Adopt servo motor driver multi-axis no pressure feeding system, no mechanical transmission error.

● Full extension type paper without rubber shaft transmission, implementation is true in the sense of "zero" damage, can prevent the deformation of cardboard and guarantee the accuracy of the paper.

● Vacuum Suction lead eage teed and adjust the paper size as per pressure of wind.

● Installing suck removing dust machine to eliminate the odd on the printing plate and improve the printing quality.

● Non side breakage technology to decrease transmission difference to min degree.

● Without equipping oil recyting and lubrication structure, and it is friendly to environment.

● Motorizedly adjustment the side breakage of feeding, controlled by touch-screen.● Both printing cylinder and impression cylinder are made of high quality steel with grounding surface and chrome plated.

● Dynamic and static balance correction ensure to run stability.

● Adopt hanging structure, convenience and fast to set up.

● Installing and uninstalling printing plate with pedal switch.

● Working with feeding unit and automatical develor system (during the feeding unit runs, the anvil roller goes down to contact with printing plate, while, on contract, leave printing plate.)

● Printing unit trasmmition is driven by servo-motor to elimate the difference.

● Printing phrase adjustment adopt touch-screen , which is finished by servo driven program automatically.

● Printing roller keep the function of zero return and can reset in dynamoic and static condition.

● Cermiacal anvil roller work with close scrapping ink stnjcture 80-150 printing line is available.

● Diaphragm pump control pump to supply and excude ink , convenience to wash.

● Duralumin arch shape scrapping ink container make anti-curved ability increase by 30% and save 20% for ink reservsion.

● Coating with friendly environment material for easy clean.

● Vacuum suction roller work with impression roller to ensure the registration precision at ± 0.35mm.

● Motorized digit dispay adjustment axial position of impression Cylinder within the range of 20mm.

● Ac servo motor work with non side breakage without gear oil supplying system to lubricate.

● Separated vacuum transport,to insure the transport precision

● Help drying, suitable shining slotting and die-cutting, good match quality

● The adjustable drying temperature control system

● Infrared ray drying system (ultraviolet ray option)● Die cutting department were driven by servo-motor indenpently to keep coordination with feeding .printing according to all kind of range of die cutter speed.

● Motor control the gap between rubber! roller and moulding roller digit display.

● Without phase adjustment and speed different compensate device, the machine still can keep the speed of die cutter equal.

● With air-operated elevator device.

● The service life of rubber cushion is longer 15%-25% than others.

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products